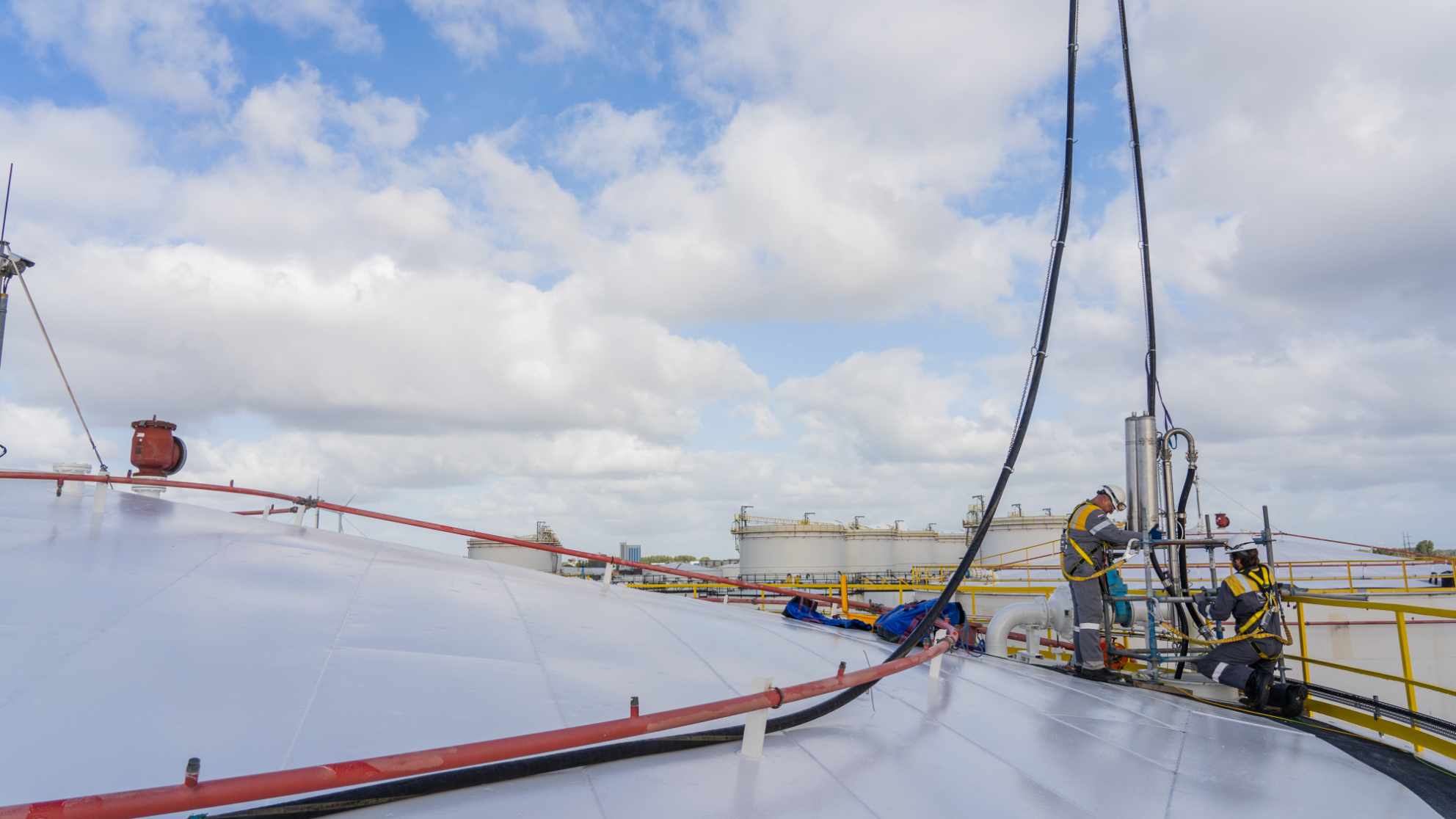

SERVICES

Ιntero Integrity Services is the only inspection and industrial services specialist worldwide which combines innovative technologies, critical insights, state-of-the-art equipment and advanced data management with a streamlined project approach.